10. Kinetics of Epoxy-Amine Curing#

10.1. 📖 Introduction#

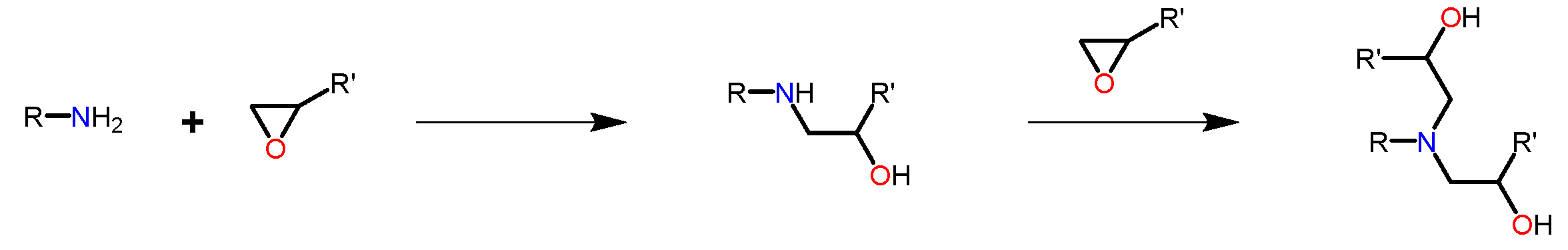

The curing of epoxy resins with polyfunctional amines is an excellent example of a step-growth polymerization resulting in a cross-linked thermoset structure. In this notebook, we will consider the reaction of a bifunctional epoxy prepolymer with a diamine. The diamine is a tetrafunctional species, since each amino hydrogen is capable of reacting with an epoxy group:

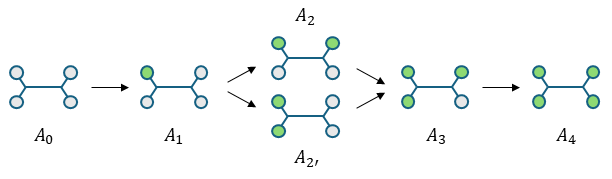

The reaction progress of a diamine molecule can be represented as a series of successive states, as shown in the following scheme:

where \(A_i\) denotes an amine molecule with \(i\) reacted amino hydrogens.

Instead of explicitly tracking each of the six possible diamine configurations, one could formulate a kinetically equivalent reaction scheme in terms of the primary and secondary amine groups only. However, the slightly more sophisticated approach chosen here has some advantages (e.g., \(M_w\) calculation), as will be seen later.

For a closed system with constant volume, the transient balances for the various species involved in the reaction network are given by:

The corresponding rate expressions are:

where \(k_1\) and \(k_2\) are apparent second-order rate coefficients that account for both the uncatalyzed and OH-catalyzed reaction pathways between an epoxy group and a primary or secondary amine, respectively. They are typically expressed as:

with \(\beta \le 1\) representing the relative reactivity of a secondary amino hydrogen compared to a primary amino hydrogen. This reduced reactivity is due to steric hindrance and electronic effects, which make secondary amines less nucleophilic than primary amines.

Interestingly, the total epoxy consumption rate can be rewritten in a simple and insightful form:

where the expressions in parentheses represent the total concentration of primary and secondary amino hydrogens, respectively.

The conversion of epoxy groups follows the standard definition:

and the overall conversion of amine groups is given by:

The evolution of the average molecular weight (until the gel point) can be calculated based on the concentration profiles of the various reacting species. In the special case of \(\beta=1\), we can employ the simple and well-known Stockmayer (1952) solution for step-growth polymerization. In general, however, the unequal reactivity of amine hydrogens complicates the analytical treatment, requiring a more powerful technique, such as the expectation theory of Miller & Macosko (1980). The full analytical expressions are provided in the documentation for polykin.stepgrowth.solutions.Miller_2, which we will use here. An important input to this function is the fraction of diamine units with exactly \(i\) reacted sites, which, in our case, is expressed as:

This last calculation step is the main reason for adopting a reaction scheme that explicitly accounts for the different diamine configurations.

Enough theory! Let’s implement this epoxy curing model and estimate the corresponding rate coefficients from experimental data.

10.2. 🧮 Model Implementation#

from copy import deepcopy

from enum import IntEnum

import matplotlib.pyplot as plt

import numpy as np

from polykin.stepgrowth.solutions import Miller_2

from scipy.integrate import solve_ivp

from scipy.optimize import minimize

For better readability, we define symbolic indices for the different species and reactions implemented in the simulation. These indices will make the code more intuitive and reduce the likelihood of errors when referencing specific components.

class Ix(IntEnum):

A0 = 0 # Amine A_0

A1 = 1 # Amine A_1

A2 = 2 # Amine A_2

A2p = 3 # Amine A_2'

A3 = 4 # Amine A_3

A4 = 5 # Amine A_4

E = 6 # Epoxy

OH = 7 # Hydroxyl

class Irxn(IntEnum):

r01 = 0 # A_0 -> A_1

r12 = 1 # A_1 -> A_2

r12p = 2 # A_1 -> A_2'

r23 = 3 # A_2 -> A_3

r2p3 = 4 # A_2'-> A_3

r34 = 5 # A_3 -> A_4

We will begin by implementing a helper function arrhenius to describe the temperature dependence of the rate coefficients.

def arrhenius(T: float, k0: float, Ea: float, T0: float) -> float:

"""Arrhenius equation.

Parameters

----------

T : float

Temperature (°C).

k0 : float

Value of rate coefficient at `T0` (#/s).

Ea : float

Energy of activation (J/mol).

T0 : float

Reference temperature (°C).

Returns

-------

float

Value of rate coefficient at `T`.

"""

R = 8.314 # J/(mol·K)

return k0 * np.exp(-Ea / R * (1/(273.15 + T) - 1/(273.15 + T0)))

Now, we implement a function to compute the derivative of the state vector, which contains the concentrations all species.

def model_xdot(t: float,

x: np.ndarray,

T: float,

params: dict,

) -> np.ndarray:

"""Calculate derivative of the state vector, dx/dt.

Parameters

----------

t : float

Time (s).

x : np.ndarray

State vector.

T : float

Temperature (°C).

params : dict

Model parameters.

Returns

-------

np.ndarray

Time derivative of the state vector.

"""

# Unpack the state vector

A0 = x[Ix.A0]

A1 = x[Ix.A1]

A2 = x[Ix.A2]

A2p = x[Ix.A2p]

A3 = x[Ix.A3]

# A4 = x[Ix.A4]

E = x[Ix.E]

OH = x[Ix.OH]

# Rate coefficients

k1u = arrhenius(T, **params['k1u'])

k1c = arrhenius(T, **params['k1c'])

beta = params['beta']

k1 = k1u + k1c*OH

k2 = beta*k1

# Reaction rates

r = np.empty(len(Irxn))

r[Irxn.r01] = 4*k1*E*A0

r[Irxn.r12] = 2*k1*E*A1

r[Irxn.r12p] = k2*E*A1

r[Irxn.r23] = 2*k2*E*A2

r[Irxn.r2p3] = 2*k1*E*A2p

r[Irxn.r34] = 1*k2*E*A3

# Derivatives

xdot = np.empty_like(x)

xdot[Ix.A0] = -r[Irxn.r01]

xdot[Ix.A1] = +r[Irxn.r01] - r[Irxn.r12] - r[Irxn.r12p]

xdot[Ix.A2] = +r[Irxn.r12] - r[Irxn.r23]

xdot[Ix.A2p] = +r[Irxn.r12p] - r[Irxn.r2p3]

xdot[Ix.A3] = +r[Irxn.r23] + r[Irxn.r2p3] - r[Irxn.r34]

xdot[Ix.A4] = +r[Irxn.r34]

xdot[Ix.E] = -r.sum()

xdot[Ix.OH] = -xdot[Ix.E]

return xdot

Then, we perform the numerical integration using a suitable ODE solver. Since this system is non-stiff, we could use an explicit scheme like RK45. However, LSODA is still faster, so we use it instead.

In comparison to the previous notebooks, we have added the teval argument. This optional argument specifies the times at which the solution should be evaluated. As we will see below, it is particularly useful when fitting the model to experimental data.

def solve_model(E_0: float,

A0_0: float,

T: float,

params: dict,

tend: float,

teval: np.ndarray | None = None

) -> dict[str, np.ndarray]:

"""Solve the dynamic model.

Parameters

----------

E_0 : float

Initial concentration of epoxyde groups (mol/L).

A0_0 : float

Initial concentration of unreacted amine molecules (mol/L)

T : float

Temperature (°C).

params : dict

Model parameters.

tend : float

End simulation time (s).

teval : np.ndarray | None

Times at which the solution is to be evaluated.

Returns

-------

dict[str, np.ndarray]

times (`t`), concentrations (`x`), conversion epoxy groups (`Xe`),

conversion amine groups (`Xa`).

"""

# Initial conditions

x0 = np.zeros(len(Ix))

x0[Ix.E] = E_0

x0[Ix.A0] = A0_0

solution = solve_ivp(model_xdot,

t_span=(0.0, tend),

t_eval=teval,

y0=x0,

args=(T, params),

method='LSODA',

rtol=1e-6,

atol=1e-10)

# Unpack the solution

t = solution.t

x = solution.y

# Check mass balance

assert np.allclose(

x[Ix.A0] + x[Ix.A1] + x[Ix.A2] + x[Ix.A2p] + x[Ix.A3] + x[Ix.A4], A0_0,

rtol=1e-4), \

"Oops, mass-balance violated!"

# Conversions

Xe = 1 - x[Ix.E]/E_0

Xa = 1 - (4*x[Ix.A0] + 3*x[Ix.A1] + 2*x[Ix.A2] + 2*x[Ix.A2p] + x[Ix.A3])/(4*A0_0)

# Fraction of diamine units with `i` reacted sites

p = np.empty((4, t.size))

p[0] = x[Ix.A1]

p[1] = x[Ix.A2] + x[Ix.A2p]

p[2] = x[Ix.A3]

p[3] = x[Ix.A4]

p /= A0_0

return {'t': t, 'x': x, 'Xe': Xe, 'Xa': Xa, 'p': p}

10.3. ▶️ Run Simulation#

The key parameters consist of \(\beta\), \(k_{1u}\) and \(k_{1c}\). The ratio \(\beta\) is set to the value reported by Girard-Reydet et al. (1995), while the two kinetic rate coefficients are simply assigned plausible initial guesses. These coefficients will be estimated from experimental data later in the analysis.

params = {

'beta': 0.65,

'k1u': {

'k0': 1e-6, # L/(mol·s)

'Ea': 50e3, # J/mol

'T0': 130. # °C

},

'k1c': {

'k0': 2e-5, # L²/(mol²·s)

'Ea': 50e3, # J/mol

'T0': 130. # °C

},

'MM': {

'DGEBA': 340., # g/mol

'MCDEA': 379. # g/mol

}

}

Let’s simulate the curing of a hypothetical stoichiometric epoxy-amine mixture at 130°C and see if the results make sense.

def plot_model_solution(E_0: float,

A0_0: float,

T: float,

params: dict,

tend: float

) -> None:

"""Plot the model solution.

Parameters

----------

E_0 : float

Initial concentration of epoxyde groups (mol/L).

A0_0 : float

Initial concentration of unreacted amine molecules (mol/L)

T : float

Temperature (°C).

params : dict

Model parameters.

tend : float

End simulation time (s).

"""

# Solve the model

solution = solve_model(E_0, A0_0, T, params, tend)

# Plots

fig, ax = plt.subplots(3, 1, sharex=True, figsize=(6, 7))

fig.suptitle("Epoxy-Amine Curing")

fig.tight_layout()

t_hour = solution['t']/3600

# Concentration of amine species

for idx, name in zip([Ix.A0, Ix.A1, Ix.A2, Ix.A2p, Ix.A3, Ix.A4],

["$A_0$", "$A_1$", "$A_2$", r"$A_{2'}$", "$A_3$", "$A_4$"]):

ax[0].plot(t_hour, solution['x'][idx], label=name)

ax[0].set_ylabel("Concentration (mol/L)")

ax[0].grid(True)

ax[0].legend(loc='upper right')

# Endgroup conversions

ax[1].plot(t_hour, 1e2*solution['Xe'], label="epoxy")

ax[1].plot(t_hour, 1e2*solution['Xa'], label="amine", linestyle='--')

ax[1].set_ylabel("Conversion (%)")

ax[1].grid(True)

ax[1].legend(loc='best')

# Mn and Mw

Mn = np.full(solution['t'].size, np.nan)

Mw = Mn.copy()

igel = -1

for i in range(1, solution['t'].size):

Mn[i], Mw[i] = Miller_2(nAf=solution['x'][Ix.A0, 0],

nB2=solution['x'][Ix.E, 0]/2, f=4,

MAf=params['MM']['MCDEA'],

MB2=params['MM']['DGEBA'],

p=solution['p'][:, i])

if np.isnan(Mn[i]):

igel = i

break

ax[2].plot(t_hour, Mn, label=r"$M_n$")

ax[2].plot(t_hour, Mw, label=r"$M_w$")

ax[2].set_ylabel("Molar mass (g/mol)")

ax[2].set_yscale('log')

ax[2].grid(True)

ax[2].legend(loc='best')

# Gel point (slightly overestimated)

xgel = 1e2*solution['Xe'][igel]

ax[2].text(t_hour[igel+2], np.sqrt(Mw[1]*Mw[igel-1]),

r"$\chi_{gel}\approx$" + f"{xgel:.1f}%",

bbox=dict(facecolor="white", edgecolor="none"))

ax[2].axvline(t_hour[igel], linestyle='--')

ax[-1].set_xlabel("Time (h)")

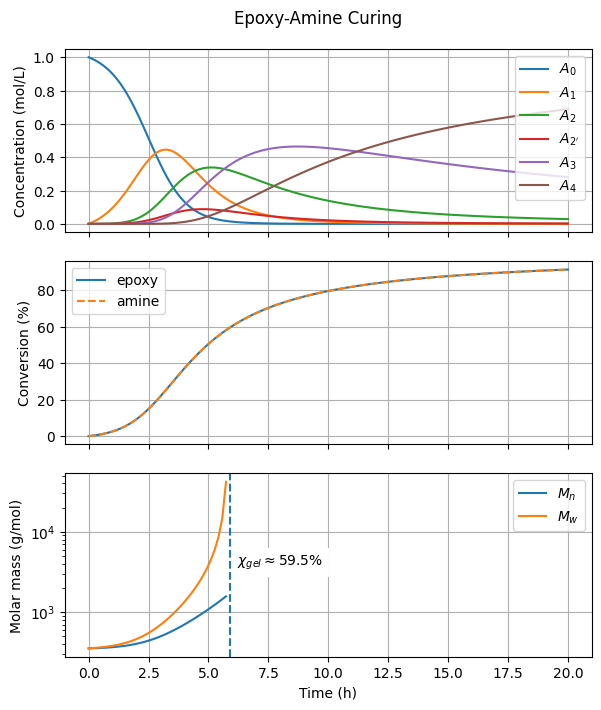

plot_model_solution(E_0=4.0, A0_0=1.0, T=130.0, params=params, tend=3600*20)

The concentration profiles of amine species (\(A_0, A_1, A_2\), etc.) exhibit the characteristic rise and fall expected in a consecutive reaction scheme. Each intermediate forms, reaches a peak, and then declines as it reacts further.

The end-group conversion profiles display a sigmoidal shape, which is typical of autocatalytic processes. Initially, the curing reaction proceeds solely via the uncatalyzed pathway. As more OH groups are formed, the OH-catalyzed pathway becomes dominant, leading to an overall increase in the reaction rate.

The conversions of epoxy and amine end groups are identical because this simulation represents an equimolar mixture. Feel free to modify the arguments E_0 and A0_0 to explore different initial conditions.

The gel point is reached at slightly below 60% conversion. As expected, this value is somewhat higher than the prediction from the Stockmayer equation, \(\chi_{gel} = \frac{1}{\sqrt{(2-1)(4-1)}} = \frac{1}{\sqrt{3}} \approx 0.58\). The discrepancy between these values increases as \(\beta\) decreases.

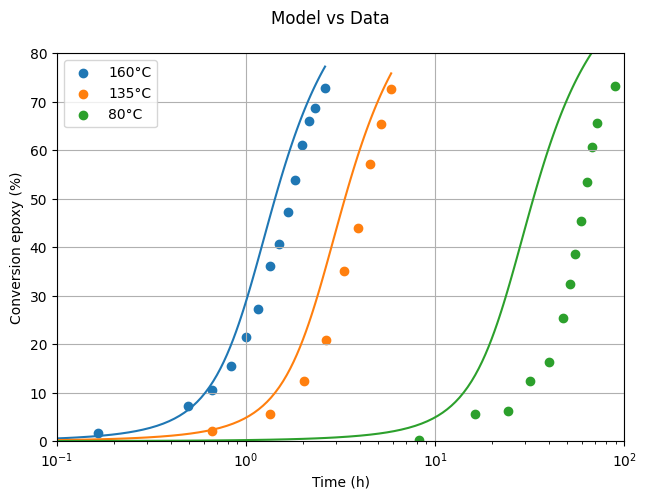

10.4. 🧪 Load experimental data#

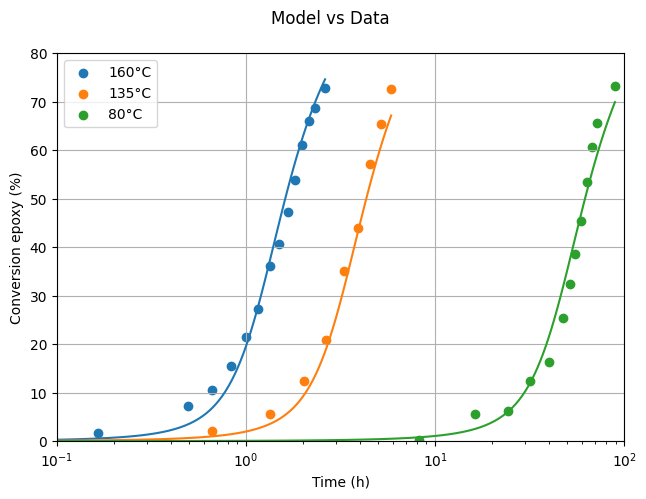

In this section, we load experimental data for the DGEBA-MCDEA system at three different temperatures from Girard-Reydet et al. (1995). The data was digitized from Figure 3b and will be used to validate our model and estimate key kinetic parameters.

data = [

{'E_0': 4.5, # mol/L

'A0_0': 4.5/4, # mol/L

'T': 160, # °C

'lnt': [2.289, 3.391, 3.678, 3.908, 4.100, 4.243, 4.382, 4.502, 4.607, 4.693, 4.780, 4.866, 4.933, 5.057], # min

'Xe': [0.016, 0.073, 0.106, 0.154, 0.214, 0.273, 0.362, 0.406, 0.472, 0.538, 0.610, 0.660, 0.688, 0.729] # -

},

{'E_0': 4.5,

'A0_0': 4.5/4,

'T': 135,

'lnt': [3.678, 4.387, 4.799, 5.067, 5.287, 5.460, 5.603, 5.738, 5.862],

'Xe': [0.020, 0.056, 0.124, 0.209, 0.351, 0.440, 0.571, 0.655, 0.727]

},

{'E_0': 4.5,

'A0_0': 4.5/4,

'T': 80,

'lnt': [6.197, 6.877, 7.280, 7.557, 7.778, 7.950, 8.036, 8.103, 8.170, 8.252, 8.305, 8.372, 8.587],

'Xe': [0.003, 0.055, 0.062, 0.124, 0.164, 0.253, 0.325, 0.387, 0.455, 0.534, 0.606, 0.656, 0.732]

}

]

The x-axis in the published figure is \(\ln t\) (min), so we convert it to time in seconds.

for d in data:

d['t'] = np.exp(d['lnt'])*60 # s

d['Xe'] = np.array(d['Xe'])

Let’s overlay the experimental data with the model predictions obtained using the initial parameter set.

def plot_model_vs_data(data: list[dict], params: dict) -> None:

"""Plot model vs data.

Parameters

----------

data : list[dict]

Experimental data sets.

params : dict

Model parameters.

"""

fig, ax = plt.subplots()

fig.suptitle("Model vs Data")

fig.tight_layout()

for d in data:

ax.scatter(d['t']/3600, 1e2*d['Xe'], label=f"{d['T']}°C")

solution = solve_model(E_0=d['E_0'],

A0_0=d['A0_0'],

T=d['T'],

params=params,

tend=d['t'][-1])

ax.plot(solution['t']/3600, 1e2*solution['Xe'])

ax.set_xlabel("Time (h)")

ax.set_xlim(1e-1, 1e2)

ax.set_ylabel("Conversion epoxy (%)")

ax.set_ylim(0.0, 80.0)

ax.set_xscale('log')

ax.grid(True)

ax.legend(loc='best')

plot_model_vs_data(data, params)

Not too bad for starters! There’s clearly room for quantitative improvement, but qualitatively, the model already reproduces the experimental trends.

10.5. 🔢 Estimate Kinetic Parameters#

To estimate the kinetic parameters, we first implement a function to evaluate the sum of squared errors (SSE) between the model predictions and the experimental results. The signature of this function is determined by the optimization routine, in our case, scipy.optimize.minimize.

def sse(p: np.ndarray) -> float:

"""Evaluate the sum of squared errors (SSE).

Parameters

----------

p : np.ndarray

Parameters to be optimized.

Returns

-------

float

The sum of squared errors (SSE).

"""

# Create a copy of the parameters to avoid modifying the original

_params = deepcopy(params)

_params['k1u']['k0'] = p[0]

_params['k1c']['k0'] = p[1]

_params['k1c']['Ea'] = p[2]

_params['k1u']['Ea'] = p[2]

result = 0.0

for d in data:

solution = solve_model(E_0=d['E_0'],

A0_0=d['A0_0'],

T=d['T'],

params=_params,

tend=d['t'][-1],

teval=d['t'])

delta = d['Xe'] - solution['Xe']

result += np.dot(delta, delta)

return result

The optimization process is performed using the minimize function with the Nelder-Mead method to estimate the parameters that minimize the sum of squared errors. The order of the parameters passed to minimize must match the order implemented in the sse function.

optsol = minimize(fun=sse,

x0=[params['k1u']['k0'],

params['k1c']['k0'],

params['k1u']['Ea']],

method='Nelder-Mead')

optsol

message: Optimization terminated successfully.

success: True

status: 0

fun: 0.04023248813073009

x: [ 4.374e-07 1.674e-05 5.803e+04]

nit: 124

nfev: 233

final_simplex: (array([[ 4.374e-07, 1.674e-05, 5.803e+04],

[ 4.374e-07, 1.674e-05, 5.803e+04],

[ 4.374e-07, 1.674e-05, 5.803e+04],

[ 4.374e-07, 1.674e-05, 5.803e+04]]), array([ 4.023e-02, 4.023e-02, 4.023e-02, 4.023e-02]))

In this case, it worked right away, but don’t take this as a rule! More often than not, you’ll need to adjust the initial guess, try different solver methods, rescale/transform the parameters (e.g., \(\log\)), and potentially include parameter bounds.

Let’s verify the results by overlaying the experimental data with the model predictions using the estimated parameters.

params_opt = deepcopy(params)

params_opt['k1u']['k0'] = optsol.x[0]

params_opt['k1c']['k0'] = optsol.x[1]

params_opt['k1u']['Ea'] = optsol.x[2]

params_opt['k1c']['Ea'] = optsol.x[2]

plot_model_vs_data(data, params_opt)

Looking at the plot, it’s clear that the model fits the experimental data quite well, showing that the estimated parameters are on point.

10.6. 🔎 Questions#

How would you describe the contribution of the OH-catalyzed pathway relative to the uncatalyzed pathway? What happens if \(k_{1u}\) is set to 0?

Formulate a simpler, yet equivalent kinetic model in terms of the amine groups (primary and secondary).