7. Radical Semibatch Copolymerization#

7.1. 📖 Introduction#

Copolymerization, in general—and radical copolymerization, in particular—is a widely used method to combine the properties of two or more monomers into a single material. In copolymerizations involving \(N\) monomers, the total number of reactions scales as \(N^2\). For example, extending the base reaction scheme presented in Notebook 3 to two monomers would yield the following:

Considering all these reactions and radical distributions in an explicit manner can quickly become overwhelming. 🤯 To reduce this complexity, we can use the pseudo-homopolymerization approach (also known as pseudo-kinetic rate constant method). This allows us to recast the copolymerization model in a form very similar to that presented for semibatch homopolymerization in Notebook 6, with only one additional state variable per monomer. Here is how it works for a binary system. The first “trick” is to lump the individual radical distributions into an overall radical distribution:

and define the corresponding radical fractions:

The second “trick” is estimate the radical fractions from the quasi-steady-state radical balances. In our case, we obtain:

with \(f_i\) being the mole fraction of monomer \(i\):

As a result, the state vector needs only to include four species (\(I\), \(M_1\), \(M_2\), \(S\)) and six moments (\(\mu_0\), \(\mu_1\), \(\mu_2\), \(\lambda_0\), \(\lambda_1\), and \(\lambda_2\)). The corresponding rates of formation are:

The average rate coefficients (also known as pseudo-kinetic rate coefficients) can be expressed in terms of the system composition at any given instant. The average propagation rate coefficient is simply given by:

For termination, different approaches exist depending on whether the termination rate is assumed to be governed by the nature of the last unit or by the overall composition of the chain. If we suppose the latter, the average termination rate coefficient can be estimated as:

where \(F_i\) denotes the instantaneous polymer composition. In contrast, the split between combination and disproportionation is more likely to depend on the nature of the terminal unit. Therefore, we might estimate the average disproportionation ratio as follows:

where \(\alpha_{ii} = k_{td,ii}/k_{t,ii}\). These are just illustrative examples, as no consensus exists on the optimal approach.

The instantaneous copolymer composition can be estimated from the Mayo-Lewis equation:

where \(r_1 = k_{p,11} / k_{p,12}\) and \(r_2 = k_{p,22} / k_{p,21}\).

Note

It can be quite tempting to think that \(p_i\) and \(F_i\) ought to be the same thing, but they are not. Can you explain why?

To complete the model, we introduce two counter variables, \(B_1\) and \(B_2\), to track the number of moles of each monomer that have reacted. These variables allow us to calculate the average molar mass of the repeating units (if the two monomers have different molar masses) and determine the cumulative copolymer composition. The corresponding rates of formation are directly related to the rates of monomer consumption:

Enough theory! Let’s write some code to solve this semibatch copolymerization model.

7.2. 🧮 Model Implementation#

The structure of this model is intentionally similar to that used in Notebook 6. However, we will remove the parts related to heat balance and temperature control, in order to keep the focus on copolymerization.

from enum import IntEnum

import matplotlib.pyplot as plt

import numpy as np

from scipy.integrate import solve_ivp

To improve code readability, we define an enum mapping the variable names to the corresponding row index in the state vector and related arrays.

class Ix(IntEnum):

I = 0

M1 = 1

M2 = 2

S = 3

mu0 = 4

mu1 = 5

mu2 = 6

lbd0 = 7

lbd1 = 8

lbd2 = 9

B1 = 10

B2 = 11

Then, we implement a helper function arrhenius to describe the temperature dependence of the rate coefficients.

def arrhenius(T: float, k0: float, Ea: float, T0: float) -> float:

"""Arrhenius equation.

Parameters

----------

T : float

Temperature (°C).

k0 : float

Value of rate coefficient at `T0` (#/s).

Ea : float

Energy of activation (J/mol).

T0 : float

Reference temperature (°C).

Returns

-------

float

Value of rate coefficient at `T`.

"""

R = 8.314 # J/(mol·K)

return k0 * np.exp(-Ea / R * (1/(273.15 + T) - 1/(273.15 + T0)))

We can now implement a function to calculate the reaction rates for all species, counters and moments.

def model_rates(C: np.ndarray, T: float, params: dict) -> tuple:

"""Reaction rates and related variables.

Parameters

----------

C : np.ndarray

Concentration vector (mol/L).

T : float

Temperature (°C).

params : dict

Model parameters.

Returns

-------

tuple

Reaction rate vector (mol/(L·s)), f_i, p_i and F_i.

"""

# Rate coefficients

kinetics = params['kinetics']

kd = arrhenius(T, **kinetics['kd'])

f = kinetics['f']

kp11 = arrhenius(T, **kinetics['kp11'])

kp22 = arrhenius(T, **kinetics['kp22'])

r1 = kinetics['r1']

r2 = kinetics['r2']

kt11 = arrhenius(T, **kinetics['kt11'])

kt22 = arrhenius(T, **kinetics['kt22'])

alpha11 = kinetics['alpha11']

alpha22 = kinetics['alpha22']

kp12 = kp11/r1

kp21 = kp22/r2

# Unpack concentrations

I = C[Ix.I]

M1 = C[Ix.M1]

M2 = C[Ix.M2]

mu = C[Ix.mu0:Ix.mu2+1]

# Monomer mole fractions

M = M1 + M2

f1 = M1/(M + 1e-10)

f2 = M2/(M + 1e-10)

# Instantaneous copolymer composition

F1 = r1*f1**2 + f1*f2

F2 = r2*f2**2 + f1*f2

Fsum = F1 + F2 + 1e-10

F1 /= Fsum

F2 /= Fsum

# Radical fractions

p1 = kp21*f1/(kp21*f1 + kp12*f2 + 1e-10)

p2 = 1 - p1

# Average kp

kp = kp11*p1*f1 + kp12*p1*f2 + kp21*p2*f1 + kp22*p2*f2

# Average kt

kt = kt11*F1 + kt22*F2

alpha = alpha11*p1**2 + 2*np.sqrt(alpha11*alpha22)*p1*p2 + alpha22*p2**2

ktd = kt*alpha

ktc = kt*(1 - alpha)

# Reaction rates

r = np.empty_like(C)

ri = 2*f*kd*I

r[Ix.I] = -kd*I

r[Ix.M1] = -(ri*f1 + (kp11*p1 + kp21*p2)*M1*mu[0])

r[Ix.M2] = -(ri*f2 + (kp12*p1 + kp22*p2)*M2*mu[0])

r[Ix.S] = 0.0

r[Ix.mu0] = ri - 2*kt*mu[0]**2

r[Ix.mu1] = ri + kp*M*mu[0] - 2*kt*mu[0]*mu[1]

r[Ix.mu2] = ri + kp*M*(mu[0] + 2*mu[1]) - 2*kt*mu[0]*mu[2]

r[Ix.lbd0] = (ktc + 2*ktd)*mu[0]**2

r[Ix.lbd1] = 2*kt*mu[0]*mu[1]

r[Ix.lbd2] = 2*kt*mu[0]*mu[2] + 2*ktc*mu[1]**2

r[Ix.B1] = - r[Ix.M1]

r[Ix.B2] = - r[Ix.M2]

return r, f1, f2, p1, p2, F1, F2

Next, we implement a function to evaluate all auxiliary variables that we wish to track over time but that are not state variables. This function will be called both during and after the integration.

def model_aux(t: float, n: np.ndarray, params: dict) -> dict:

"""Auxiliary model function.

Parameters

----------

t : float

Time (s).

n : np.ndarray

Components moles vector (mol).

params : dict

Model parameters.

Returns

-------

dict

Auxiliary variables.

"""

# Unpack the moles vector (mol)

n_I = n[Ix.I]

n_M1 = n[Ix.M1]

n_M2 = n[Ix.M2]

n_S = n[Ix.S]

n_B1 = n[Ix.B1]

n_B2 = n[Ix.B2]

# Temperature

T = params['T'](t)

# Total mass of the reaction mixture (kg)

MW = params['MW']

m_t = n_I*MW['I'] + (n_M1 + n_B1)*MW['M1'] + (n_M2 + n_B2)*MW['M2'] \

+ n_S*MW['S']

# Total volume of the reaction mixture (L)

rho = params['rho']

V = n_M1*(MW['M1']/rho['M1']) + n_M2*(MW['M2']/rho['M2']) \

+ n_B1*(MW['M1']/rho['P1']) + n_B2*(MW['M2']/rho['P2']) \

+ n_S*(MW['S']/rho['S'])

# Molar concentrations (mol/L)

C = n/(V + 1e-10)

# Reaction rates (L/(mol.s)) and related variables

r, f1, f2, p1, p2, F1, F2 = model_rates(C, T, params)

# Component molar feed rates (mol/s)

feed = params['feed']

ndot_in = np.zeros_like(n)

ndot_in[Ix.I] = feed['I'](t)

ndot_in[Ix.M1] = feed['M1'](t)

ndot_in[Ix.M2] = feed['M2'](t)

ndot_in[Ix.S] = feed['S'](t)

# Pack variables in dict

y = {

'm_t': m_t,

'V': V,

'C': C,

'r': r,

'f1': f1,

'f2': f2,

'p1': p1,

'p2': p2,

'F1': F1,

'F2': F2,

'ndot_in': ndot_in,

'T': T

}

return y

All parts are now in place to implement the derivative of the state vector. This function is relatively straightforward, as most of the heavy lifting is handled by the previously defined functions.

def model_xdot(t: float, x: np.ndarray, params: dict) -> np.ndarray:

"""Calculate the derivative of the state vector, dx/dt.

x = [n(I), n(M1), n(M2), n(S), n(mu_0)..n(mu_2), n(lambda_0)..n(lambda_2)]

Parameters

----------

t : float

Time (s).

x : np.ndarray

State vector.

params : dict

Model parameters.

Returns

-------

np.ndarray

Time derivative of the state vector.

"""

# Unpack the state vector

n = x

# Allocate the state vector derivative and respective views

xdot = np.zeros_like(x)

ndot = xdot[:]

# Evaluate the auxiliary variables

y = model_aux(t, n, params)

# Material balances

ndot_in = y['ndot_in']

r = y['r']

V = y['V']

ndot[:] = ndot_in + r*V

return xdot

Finally, we perform the numerical integration using a suitable ODE solver. This system is very stiff, therefore we need to choose an implicit solver like LSODA.

def solve_model(n0: np.ndarray,

params: dict,

tend: float,

) -> tuple[np.ndarray, ...]:

"""Solve the dynamic model.

Parameters

----------

n0 : float

Initial component moles (mol).

params : dict

Model parameters.

tend : float

End simulation time.

Returns

-------

tuple[np.ndarray, ...]

t, n, T, m_t, V, ndot_in, C, f1, f2, F1, F2.

"""

# Initial conditions

x0 = n0

solution = solve_ivp(model_xdot,

t_span=(0.0, tend),

y0=x0,

args=(params,),

method='LSODA',

rtol=1e-4,

atol=1e-11,

max_step=600.)

# Unpack the solution

t = solution.t

x = solution.y

n = x

# Compute aux variables

m_t = np.empty_like(t)

V = np.empty_like(t)

C = np.empty_like(n)

f1 = np.empty_like(t)

f2 = np.empty_like(t)

F1 = np.empty_like(t)

F2 = np.empty_like(t)

ndot_in = np.empty_like(n)

T = np.empty_like(t)

for i in range(t.size):

y = model_aux(t[i], n[:, i], params)

m_t[i] = y['m_t']

V[i] = y['V']

C[:, i] = y['C']

ndot_in[:, i] = y['ndot_in']

T[i] = y['T']

f1[i] = y['f1']

f2[i] = y['f2']

F1[i] = y['F1']

F2[i] = y['F2']

return t, n, T, m_t, V, ndot_in, C, f1, f2, F1, F2

7.3. ▶️ Run Simulation#

We will use some educated guesses for an imaginary solution copolymerization. Feel free to change them.

params = {

'MW': {

'I': 0.150, # kg/mol

'M1': 0.100, # kg/mol

'M2': 0.140, # kg/mol

'S': 0.100, # kg/mol

},

'rho': {

'M1': 0.90, # kg/L

'M2': 0.95, # kg/L

'S': 0.80, # kg/L

'P1': 1.10, # kg/L

'P2': 1.15, # kg/L

},

'kinetics': {

'f': 0.5,

'alpha11': 0.2,

'alpha22': 0.8,

'r1': 0.5,

'r2': 2.0,

'kd': {

'k0': 5e-4, # 1/s

'Ea': 50e3, # J/mol

'T0': 80. # °C

},

'kp11': {

'k0': 2e3, # L/(mol·s)

'Ea': 20e3, # J/mol

'T0': 80. # °C

},

'kp22': {

'k0': 1e3, # L/(mol·s)

'Ea': 15e3, # J/mol

'T0': 80. # °C

},

'kt11': {

'k0': 5e7, # L/(mol·s)

'Ea': 10e3, # J/mol

'T0': 80. # °C

},

'kt22': {

'k0': 3e7, # L/(mol·s)

'Ea': 12e3, # J/mol

'T0': 80. # °C

},

},

'T': lambda t: np.interp(t, [0., 1800., 11*3600.], [20., 80., 80.]),

'feed': {

'I': lambda t: 2e-2 if (t > 1800. and t < 8*3600.) else 0., # mol/s

'M1': lambda t: 1.2 if (t > 1800. and t < 6*3600.) else 0., # mol/s

'M2': lambda t: 0.8 if (t > 1800. and t < 6*3600.) else 0., # mol/s

'S': lambda t: 3e0 if (t > 1800. and t < 6*3600.) else 0., # mol/s

},

}

# Initial reactor content

n0 = np.zeros(len(Ix))

n0[Ix.I] = 0.0

n0[Ix.M1] = 0.0

n0[Ix.M2] = 0.0

n0[Ix.S] = 1e4

# Simulation time

tend = 10*3.6e3

Finally, we perform the integration; this should not take more than a fraction of a second, since there is only a dozen states.

t, n, T, m_t, V, ndot_in, C, f1, f2, F1, F2 = solve_model(n0, params, tend)

7.4. 📊 Plots#

Now, let’s visualize the model results.

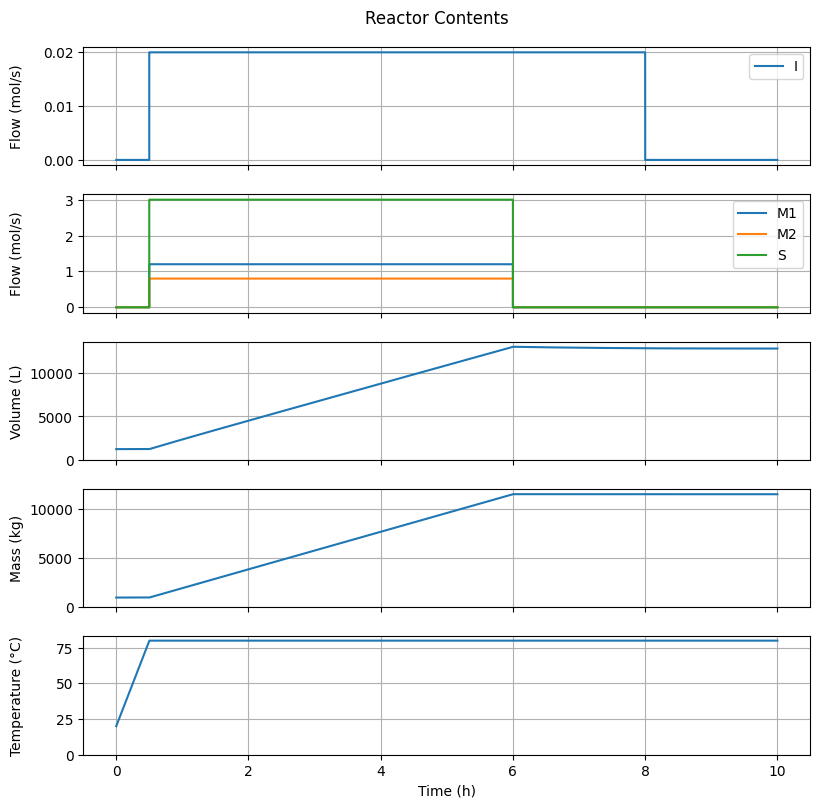

7.4.1. Reactor Contents#

fig1, ax = plt.subplots(5, 1, sharex=True, figsize=(8, 8))

fig1.suptitle("Reactor Contents")

fig1.tight_layout()

fig1.align_ylabels()

t_hour = t/3.6e3

# Feed I

ax[0].plot(t_hour, ndot_in[Ix.I, :], label="I")

ax[0].set_ylabel("Flow (mol/s)")

ax[0].grid(True)

ax[0].legend(loc='upper right')

# Feed others

for species in ["M1", "M2", "S"]:

ax[1].plot(t_hour, ndot_in[getattr(Ix, species), :], label=species)

ax[1].set_ylabel("Flow (mol/s)")

ax[1].grid(True)

ax[1].legend(loc='upper right')

# Volume

ax[2].plot(t_hour, V)

ax[2].set_ylabel("Volume (L)")

ax[2].set_ylim(0.0, None)

ax[2].grid(True)

# Mass

ax[3].plot(t_hour, m_t)

ax[3].set_ylabel("Mass (kg)")

ax[3].set_ylim(0.0, None)

ax[3].grid(True)

# Temperature

ax[4].plot(t_hour, T)

ax[4].set_ylabel("Temperature (°C)")

ax[4].set_ylim(0.0, None)

ax[4].grid(True)

ax[-1].set_xlabel("Time (h)")

Text(0.5, 58.7222222222222, 'Time (h)')

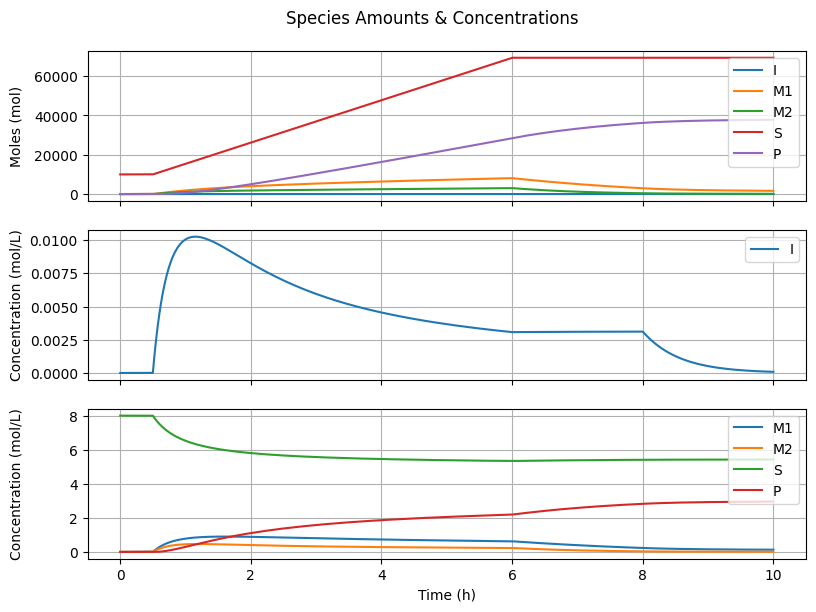

7.4.2. Species Amounts & Concentrations#

fig2, ax = plt.subplots(3, 1, sharex=True, figsize=(8, 6))

fig2.suptitle("Species Amounts & Concentrations")

fig2.tight_layout()

fig2.align_ylabels()

# Number of moles

for species in ["I", "M1", "M2", "S"]:

ax[0].plot(t_hour, n[getattr(Ix, species), :], label=species)

ax[0].plot(t_hour, n[Ix.mu1, :] + n[Ix.lbd1, :], label="P")

ax[0].set_ylabel("Moles (mol)")

ax[0].grid(True)

ax[0].legend(loc='upper right')

# Molar concentration I

ax[1].plot(t_hour, C[Ix.I, :], label="I")

ax[1].set_ylabel("Concentration (mol/L)")

ax[1].grid(True)

ax[1].legend(loc='upper right')

# Molar concentrations others

for species in ["M1", "M2", "S"]:

ax[2].plot(t_hour, C[getattr(Ix, species), :], label=species)

ax[2].plot(t_hour, C[Ix.mu1, :] + C[Ix.lbd1, :], label="P")

ax[2].set_ylabel("Concentration (mol/L)")

ax[2].grid(True)

ax[2].legend(loc='upper right')

ax[-1].set_xlabel("Time (h)")

Text(0.5, 36.72222222222221, 'Time (h)')

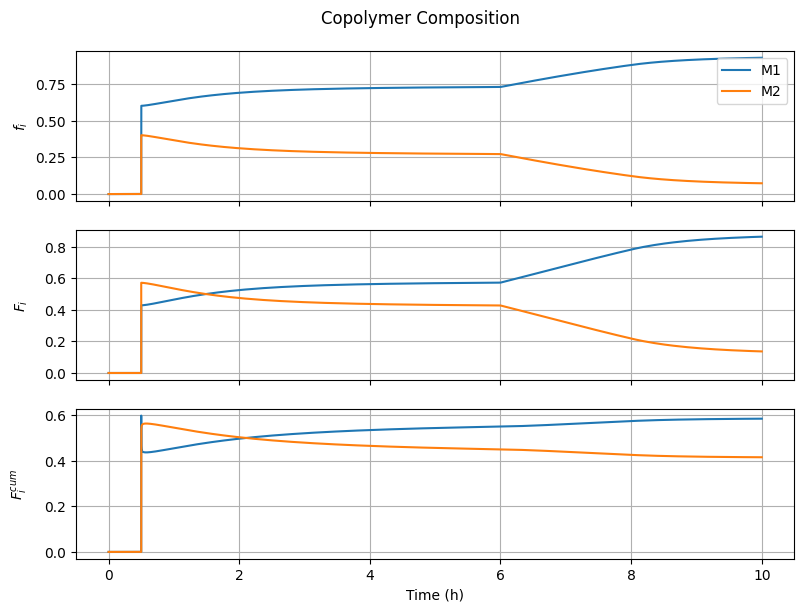

7.4.3. Copolymer Composition#

fig3, ax = plt.subplots(3, 1, sharex=True, figsize=(8, 6))

fig3.suptitle("Copolymer Composition")

fig3.tight_layout()

fig3.align_ylabels()

# Monomer composition

ax[0].plot(t_hour, f1, label="M1")

ax[0].plot(t_hour, f2, label="M2")

ax[0].set_ylabel(r"$f_i$")

ax[0].grid(True)

ax[0].legend(loc='upper right')

# Instantaneous copolymer composition

ax[1].plot(t_hour, F1, label="M1")

ax[1].plot(t_hour, F2, label="M2")

ax[1].set_ylabel(r"$F_i$")

ax[1].grid(True)

# Cumulative copolymer composition

F1cum = n[Ix.B1, :]/(n[Ix.B1, :] + n[Ix.B2, :] + 1e-10)

F2cum = n[Ix.B2, :]/(n[Ix.B1, :] + n[Ix.B2, :] + 1e-10)

ax[2].plot(t_hour, F1cum, label="M1")

ax[2].plot(t_hour, F2cum, label="M2")

ax[2].set_ylabel(r"$F_i^{cum}$")

ax[2].grid(True)

ax[-1].set_xlabel("Time (h)")

Text(0.5, 36.72222222222221, 'Time (h)')

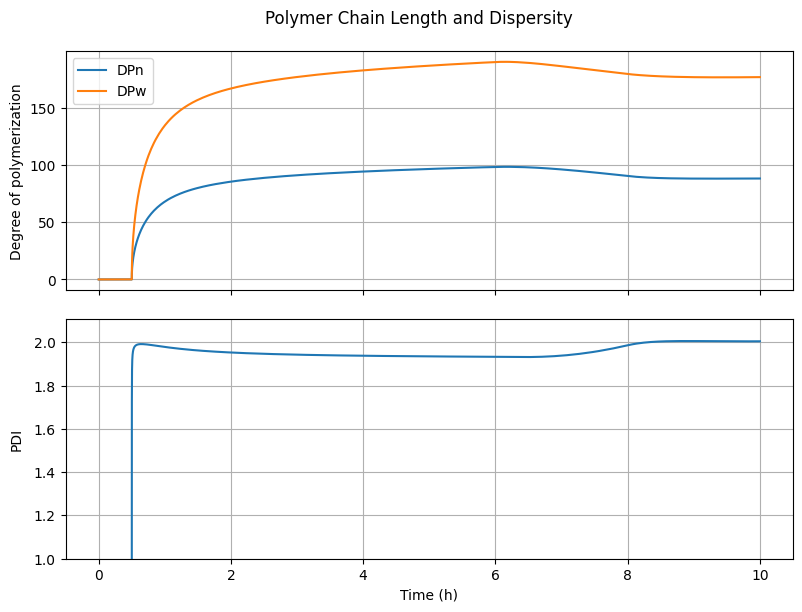

7.4.4. Polymer Chain Length and Dispersity#

fig4, ax = plt.subplots(2, 1, sharex=True, figsize=(8, 6))

fig4.suptitle("Polymer Chain Length and Dispersity")

fig4.tight_layout()

fig4.align_ylabels()

# DPn and DPw

DPn = (n[Ix.mu1, :] + n[Ix.lbd1, :])/(n[Ix.mu0, :] + n[Ix.lbd0, :] + 1e-10)

DPw = (n[Ix.mu2, :] + n[Ix.lbd2, :])/(n[Ix.mu1, :] + n[Ix.lbd1, :] + 1e-10)

ax[0].plot(t_hour, DPn, label="DPn")

ax[0].plot(t_hour, DPw, label="DPw")

ax[0].set_ylabel("Degree of polymerization")

ax[0].grid(True)

ax[0].legend(loc='best')

# PDI

PDI = DPw/(DPn + 1e-10)

ax[1].plot(t_hour, PDI)

ax[1].set_ylabel("PDI")

ax[1].set_ylim(1.0, None)

ax[1].grid(True)

ax[-1].set_xlabel("Time (h)")

Text(0.5, 36.72222222222221, 'Time (h)')

7.5. 🔎 Questions#

Experiment with different monomer and initiator dosing profiles to understand their impact on chain length and copolymer composition.

Propose one or more alternative feed strategies that enhance composition control while maintaining the average chain length.